We specialize in precision injection molding, offering end-to-end services from design optimization, mold development to mass production. No matter when or where, our engineering team is on standby 24/7 to ensure your project needs receive immediate response—whether it's last-minute midnight modifications or urgent holiday orders, we're always online. With our uninterrupted service commitment, we safeguard your product manufacturing.

Basic Information

The customer needs a housing for an intercom system that must be lightweight yet sturdy, with precise dimensions to perfectly match the internal components. Additionally, the chosen material should offer excellent resistance to impacts, scratches, and wear. Also need to ensure affordable price.

| Manufacturing Process | Plastic Mold Making Service |

| Parts Material | ABS |

| Mold Type | Hard Tooling |

| Application Industry | Communication devices /electronic |

| Surface Treatment | Glossy |

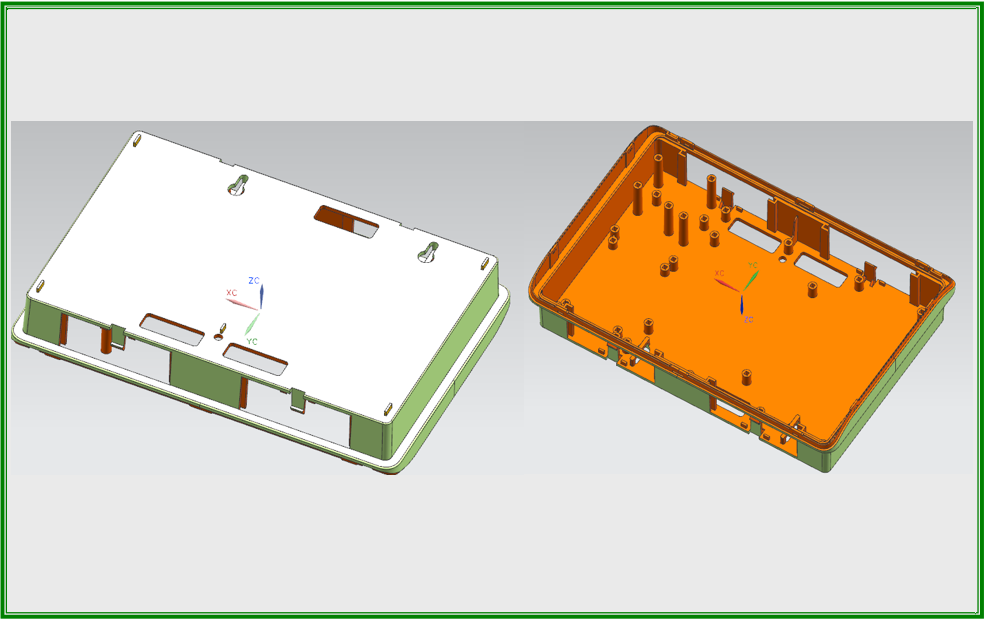

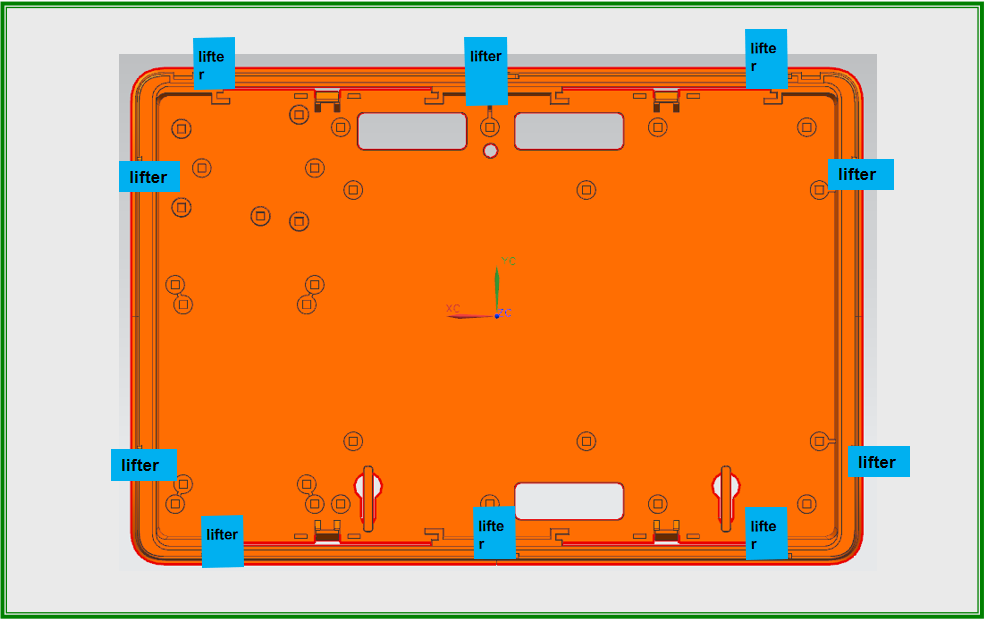

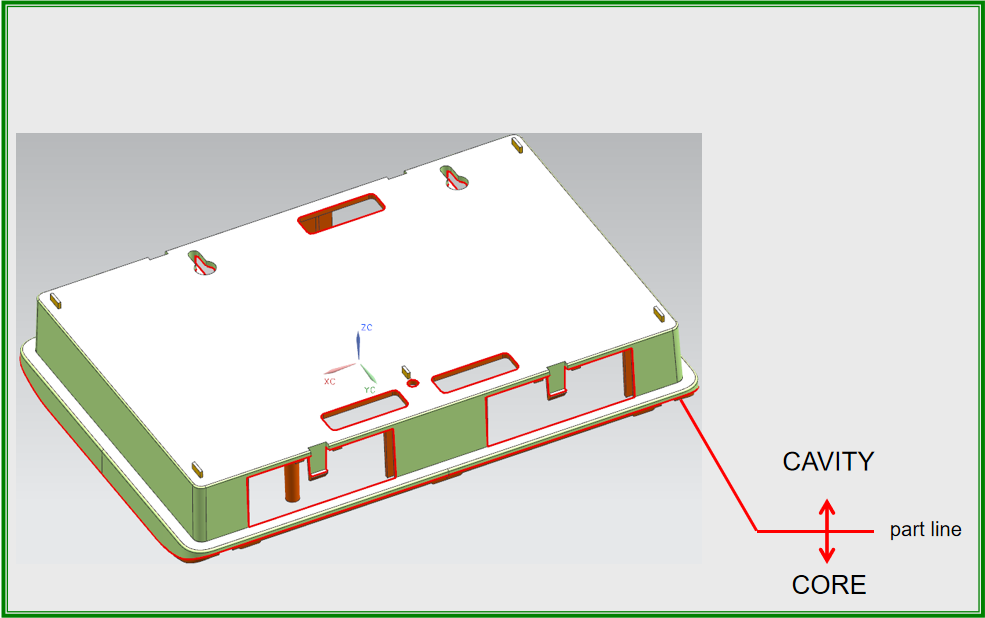

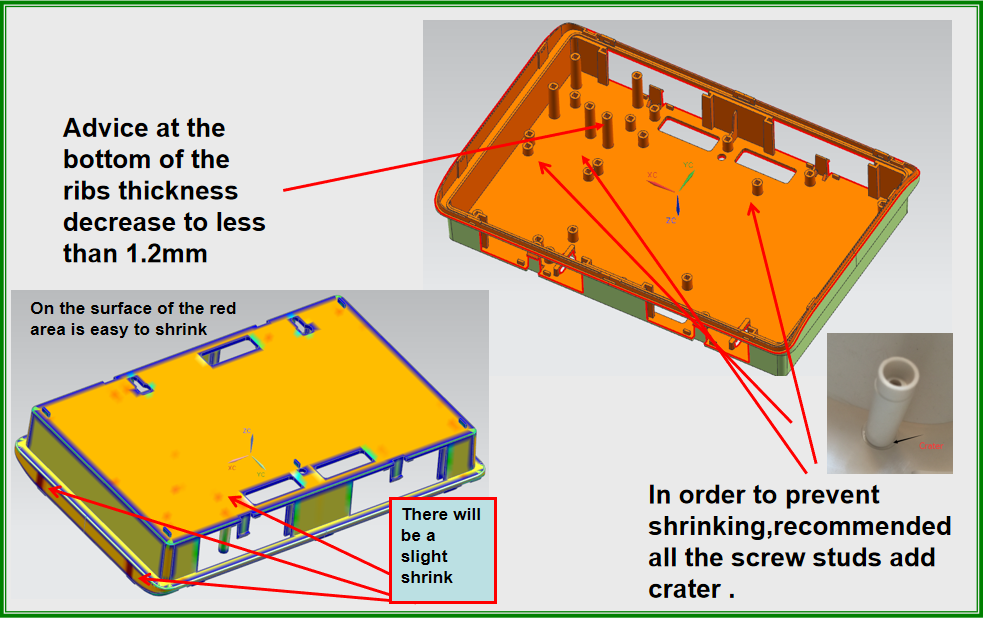

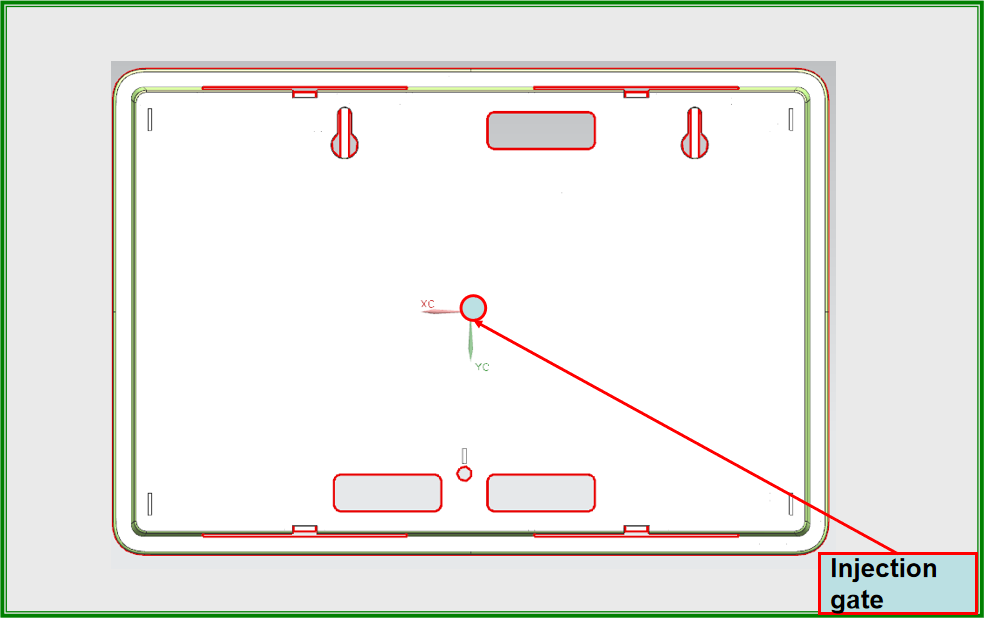

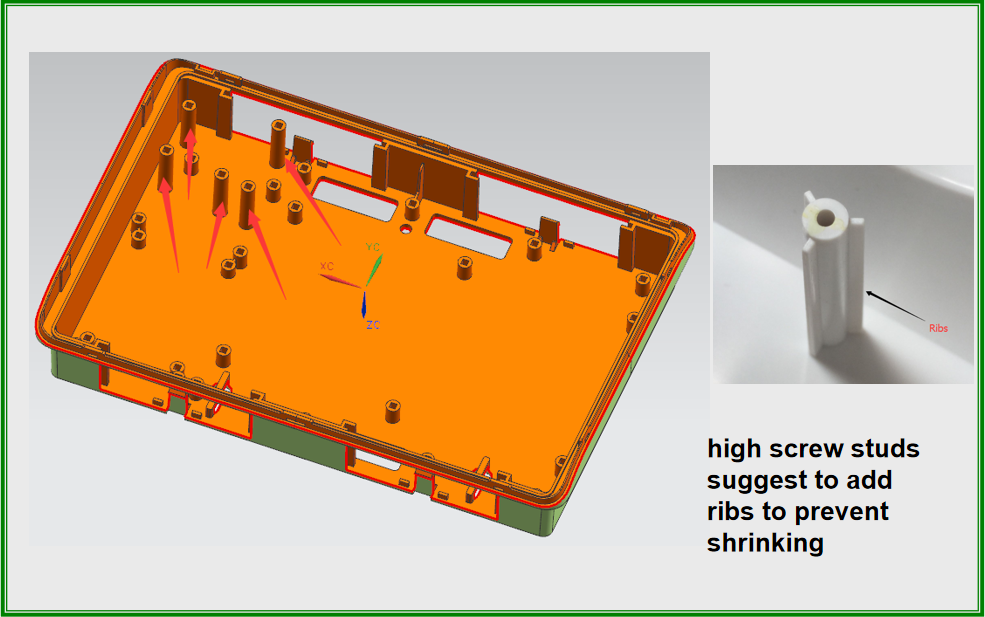

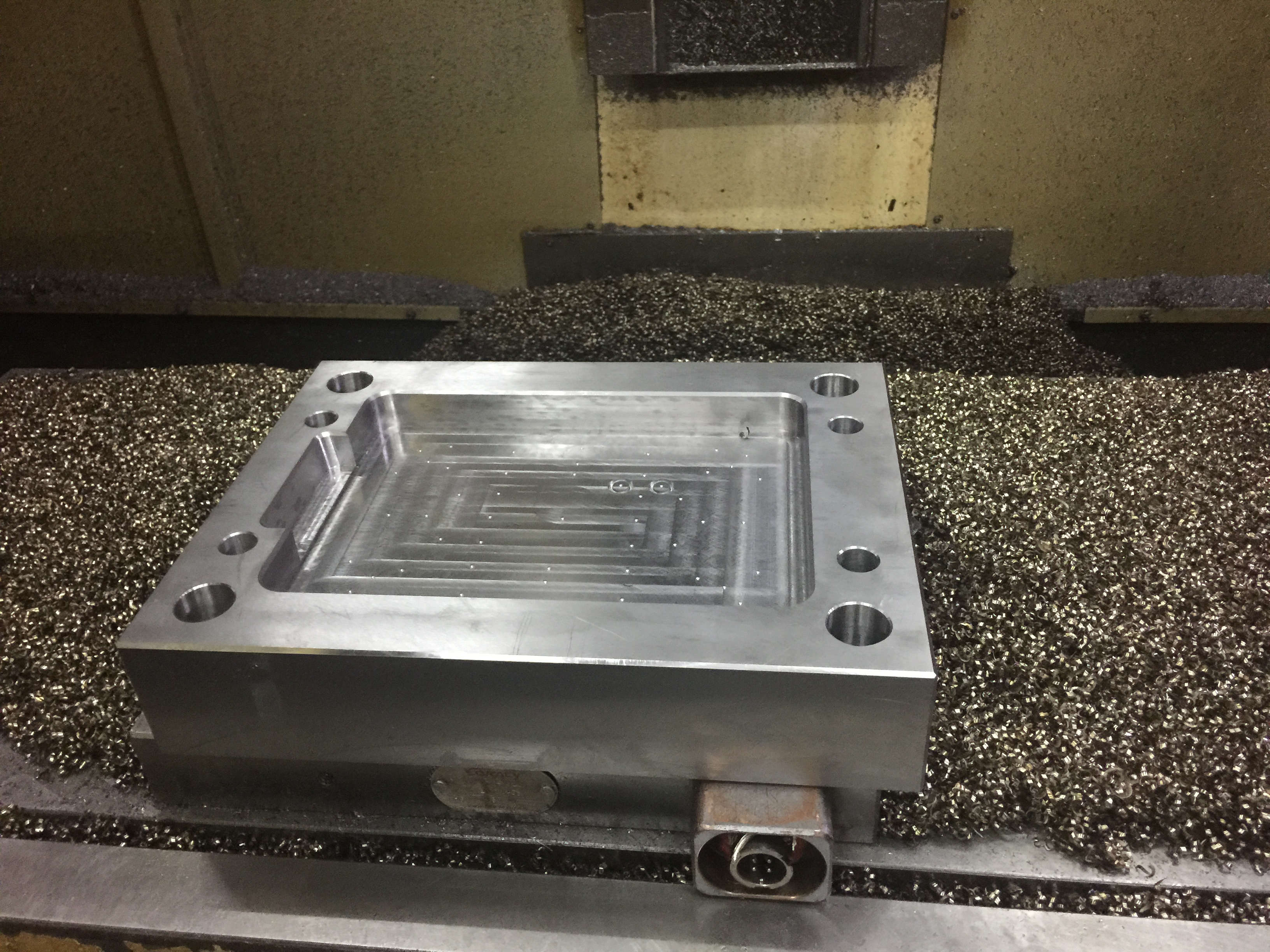

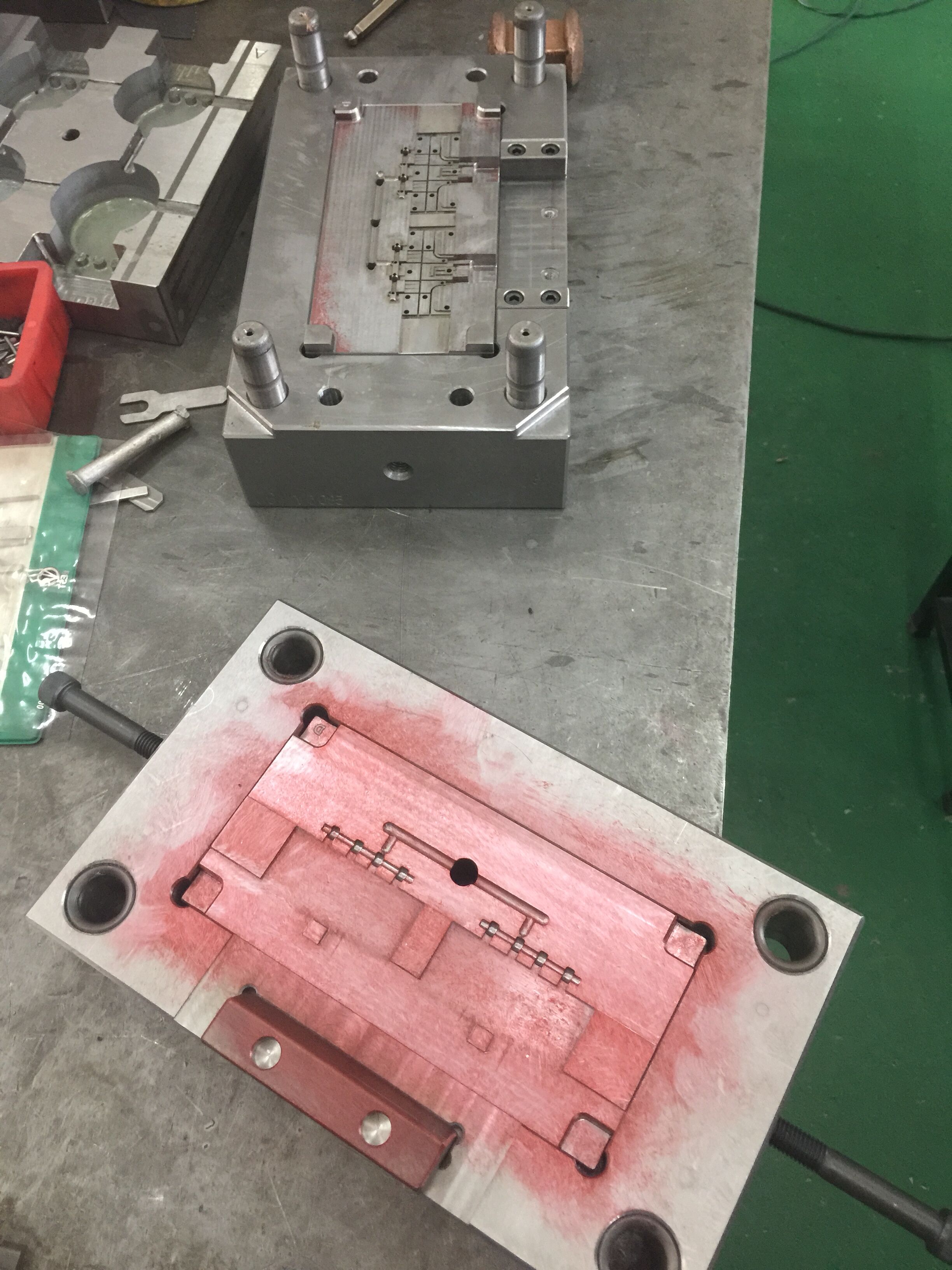

DFM analysis and Mold design

Challenges:

Although the client required a lightweight yet durable plastic injection-molded housing for their intercom system, the production process encountered multiple difficulties. The housing needed to maintain high environmental resistance (dustproof, shockproof, and corrosion-resistant) under harsh conditions while ensuring precise dimensions to fit internal electronic components, all within strict cost constraints for mass production.

Solution:

We employed high-performance engineering plastics (such as PC/ABS alloy) to optimize material properties and refined mold design along with injection molding parameters. This approach ensured the housing achieved an ideal balance of lightweight construction, impact resistance, and dimensional accuracy. The final product met IP67 protection standards while maintaining cost efficiency for large-scale manufacturing.

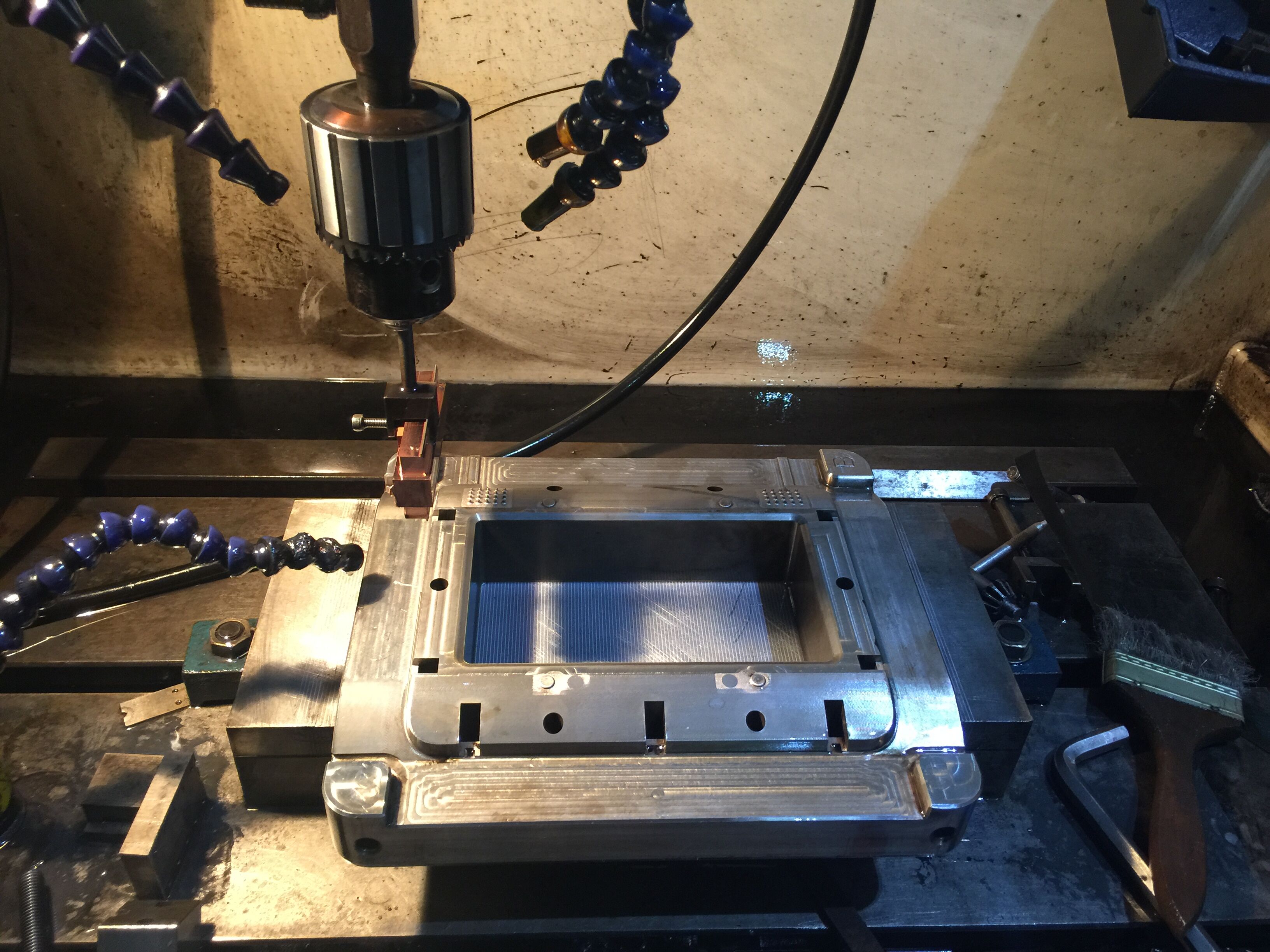

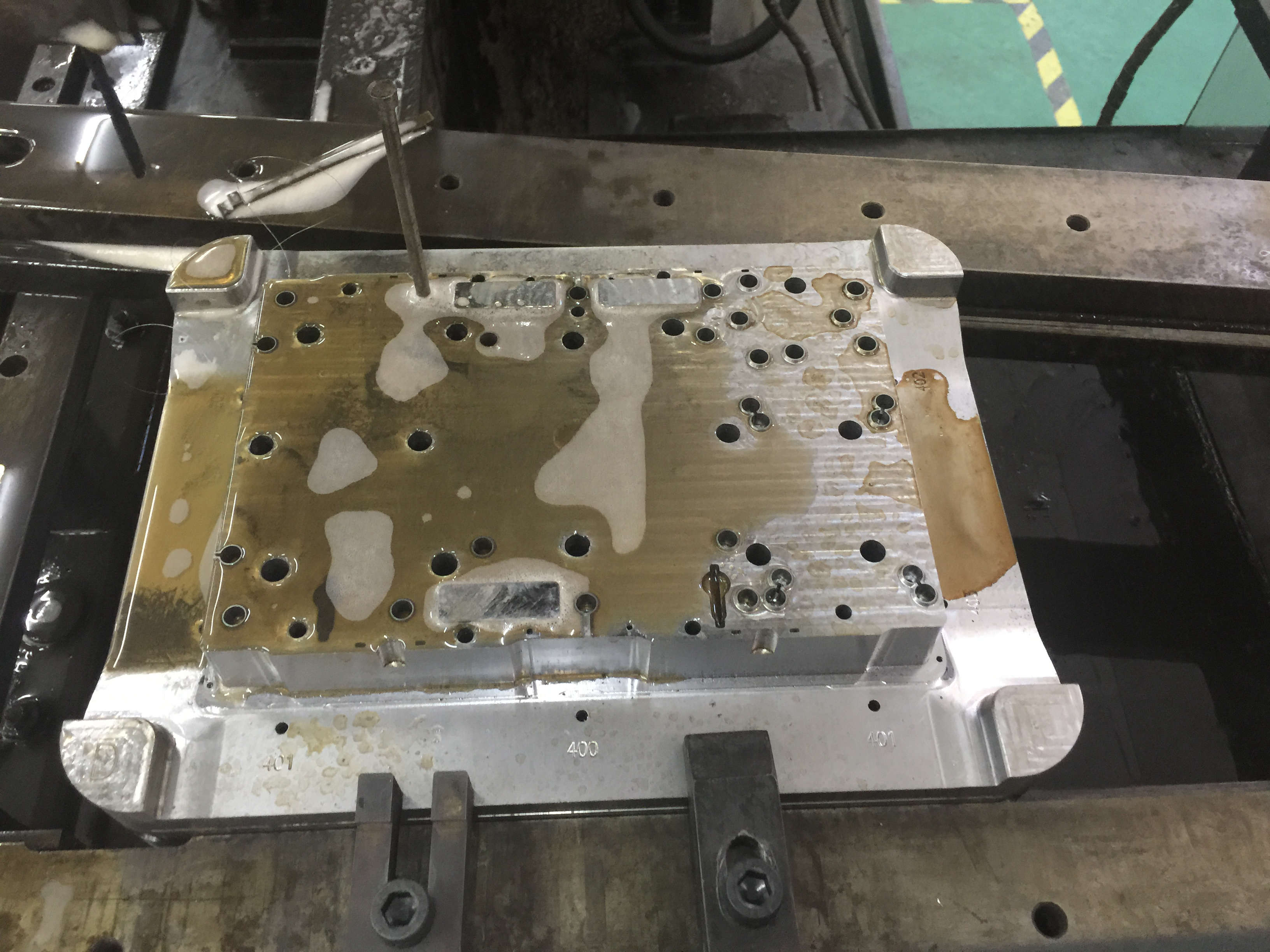

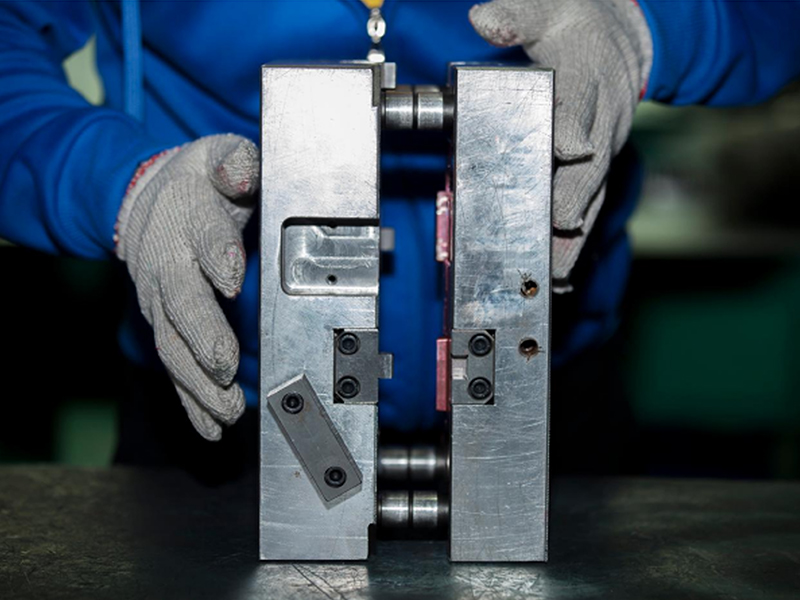

Mould processing and debugging

Project Outcome:

We successfully achieved mass production of the product for our client, with customized packaging solutions tailored to product specifications and optimized logistics to ensure secure transportation. From precision injection molding to final delivery, we maintained strict quality and efficiency control throughout the entire process, providing a complete solution that balances cost-effectiveness and reliability.

If you require professional injection molding services, contact us now—our technical team is available 24/7 to provide dedicated support!

Post time: Apr-28-2025